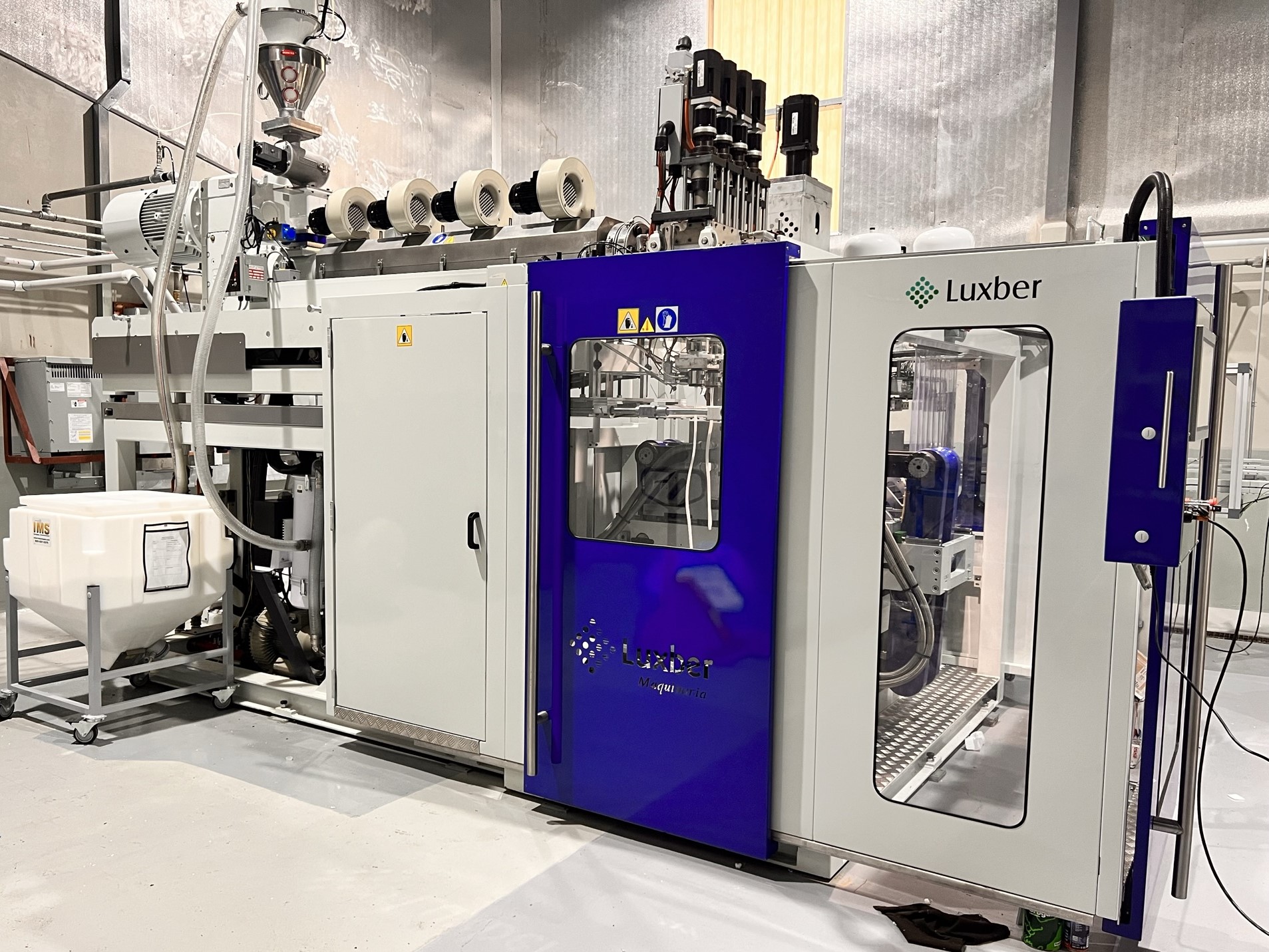

LUXBER EXTRUSION BLOW MOULDERS

FEATURES

- Industry Leading Energy Efficiency

- Compact Footprint

- IML and Coex Options

- Fast Change Over Format Option

- Industry 4.0 Controls

- Meets NA Safety and Electrical Standards

Introducing our state-of-the-art Extrusion Blow Moulding Machines, a revolutionary product designed with industry-leading energy efficiency. Equipped with B&R Automation Industry 4.0 Controls, these machines offer a compact footprint, ensuring optimal utilization of your workspace. They deliver fully deflashed containers, ensuring the highest quality of output. With a fast changeover of formats, these machines provide flexibility and adaptability to your production needs.

Our Extrusion Blow Moulding Machines come in both single and double station models, providing options to suit your specific requirements. They also offer In-Mould Labelling (IML) and Coextrusion (Coex) options, enhancing the versatility of your production capabilities. These machines meet North American Safety and Electrical Standards, ensuring a safe and compliant operation. As shuttle type machines, they are suitable for the production of plastic bottles ranging from 2 ml to 35 litres, catering to a wide spectrum of your production needs.

Varies Based on Model